Type Design & Fabrication Workshop

Tools Laser cutter, pop rivet guns

Date 5th – 7th, 12th – 13th Aug 2016

Location Fab Lab Berlin | DE

Tutor Agata Kycia & Patrick Bedarf

Participants Maria Selkou, Natalie Peter, Kai Peter, Charlie-Camille Thomas, Romana Scholz, Werner Budde, Anna-Amalia Gräwe, Park Geun Woo

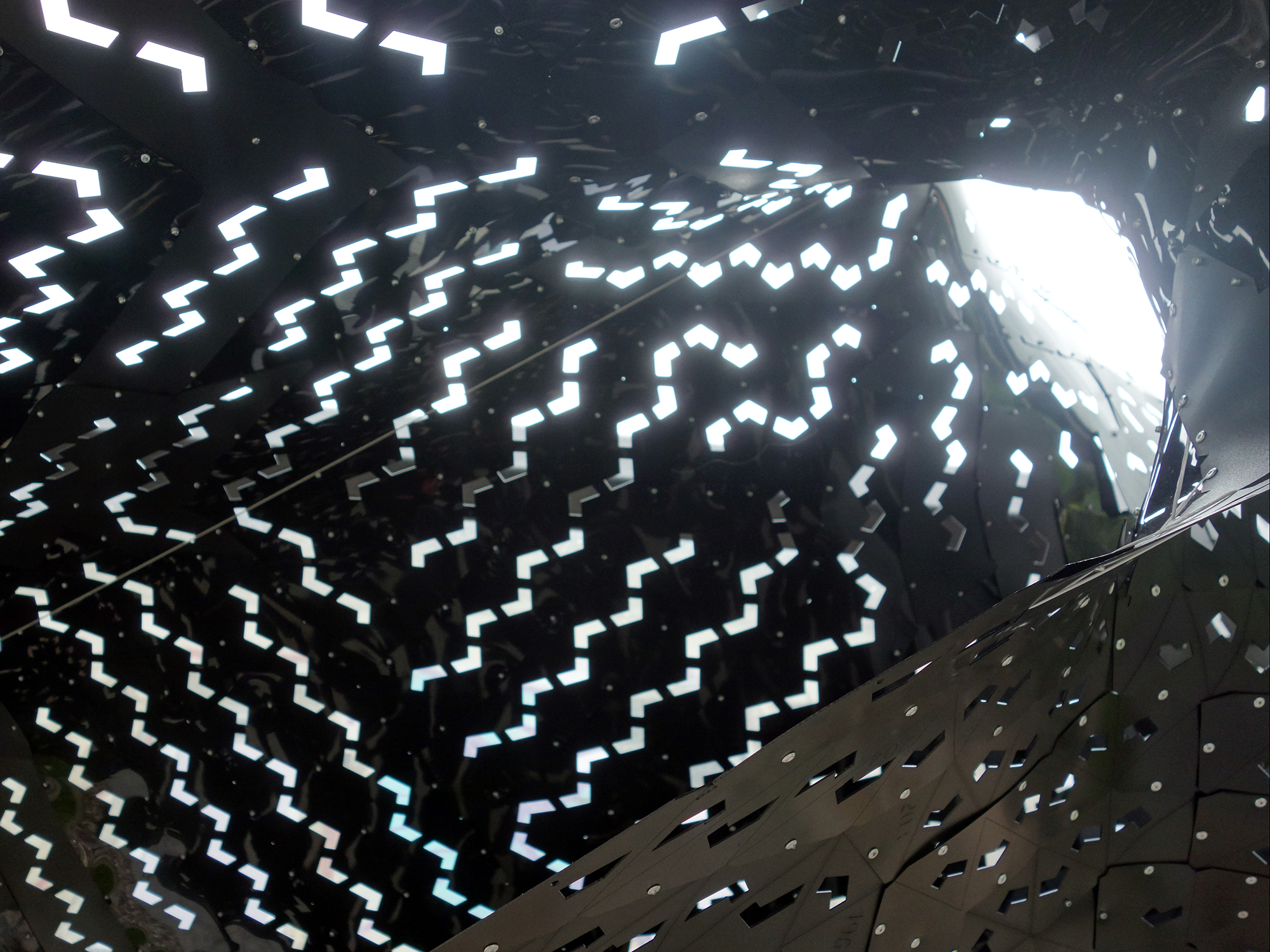

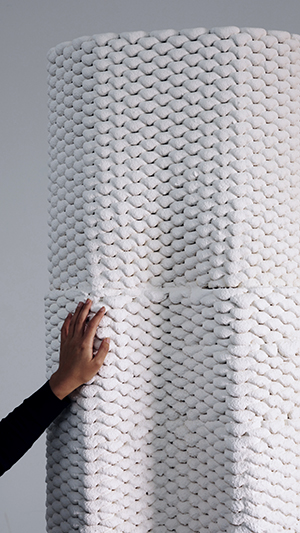

MESHWORKS BERLIN builds upon previous workshops investigating complex mesh topologies and fabrication assemblies. The five day event was tailored for the Fab Lab Berlin community of design and fabrication enthusiasts and provided quick paced introduction to Rhino/Grasshopper with its particular plug-ins Kangaroo, Ivy and Weaverbird, full workflow of parametric design and simulation as well as fabrication planning and execution of a full-scale spatial installation. Hereby, the particular focus was put on force-based form-finding design of a convoluted geometry, which could be assembled of lasercut components from 20 m² black POM sheets (0.8 mm), pop rivets as well as steel cables and clip connectors. Consequently, the workshop was structured in two consecutive weekend blocks, with a separation into (1) computational design accompanied by lectures, technical training sessions as well as material testing and (2) fabrication and assembly.

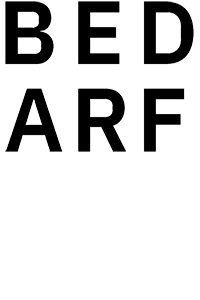

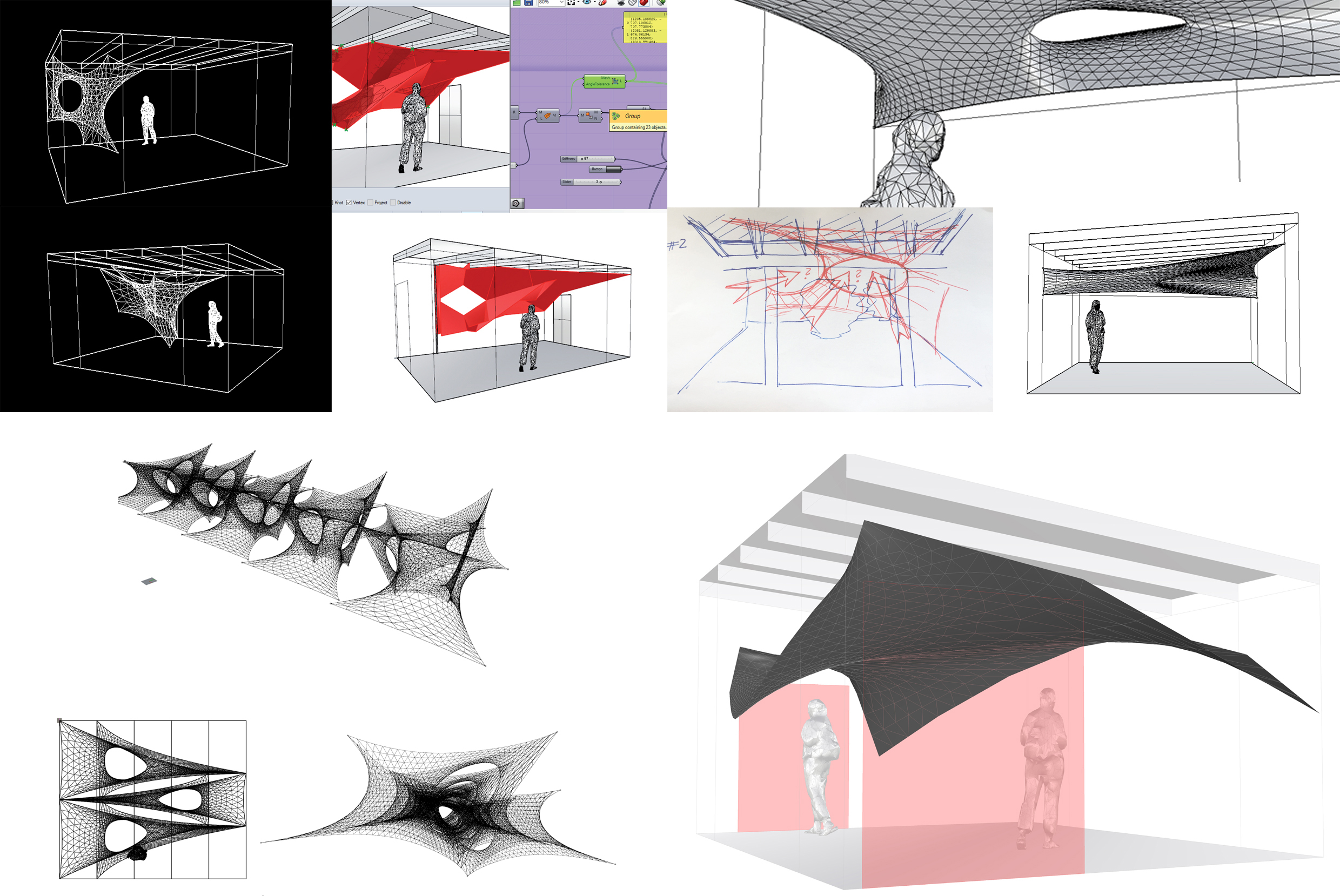

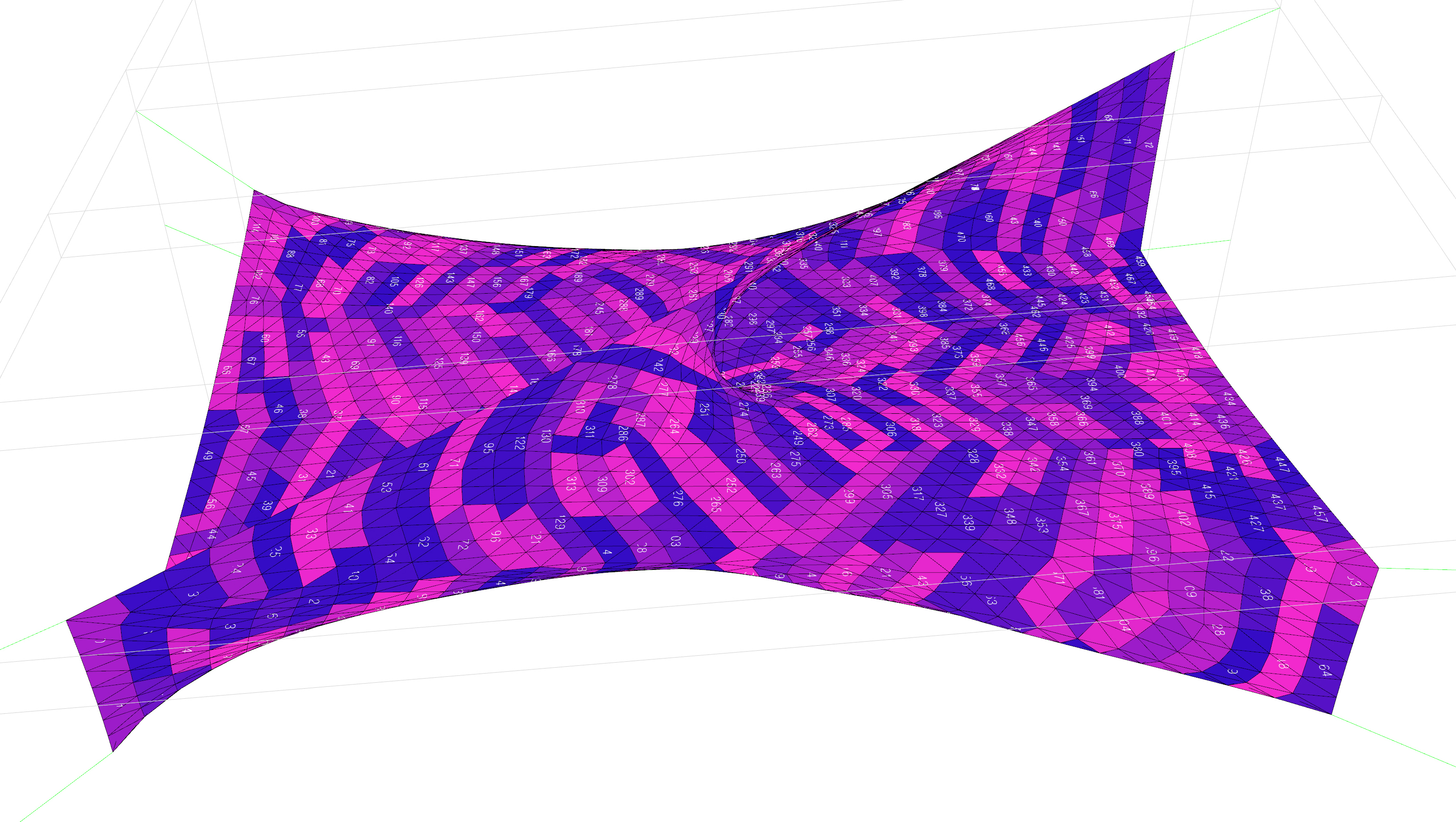

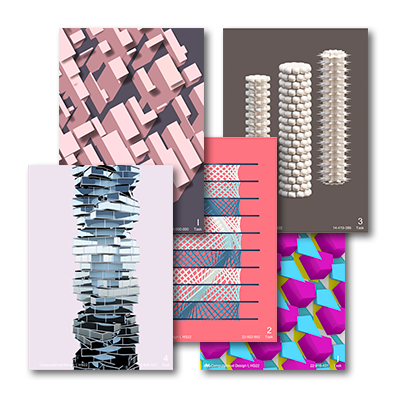

Force-Based Design During the first weekend participants were introduced to computational form finding methods and fabrication oriented geometry discretization. After initial studies on possible site interventions the Kangaroo physics engine was utilized for mesh relaxation based on low-poly input geometry. These models were evaluated and optimized regarding their spatial qualities and performance of material consumption, laser and assembly time. A democratically voted chimera of each team’s features was finalized for further processing.

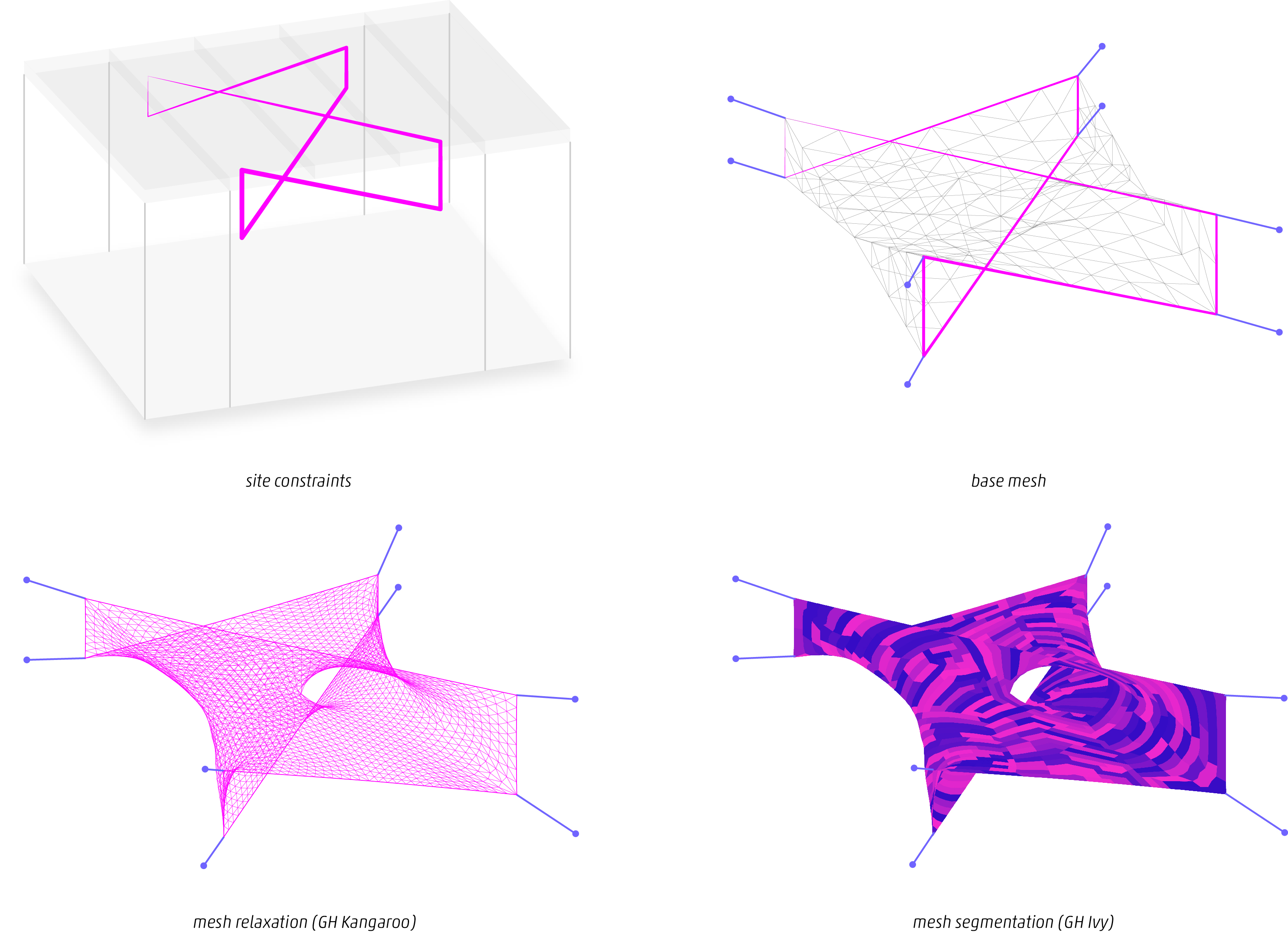

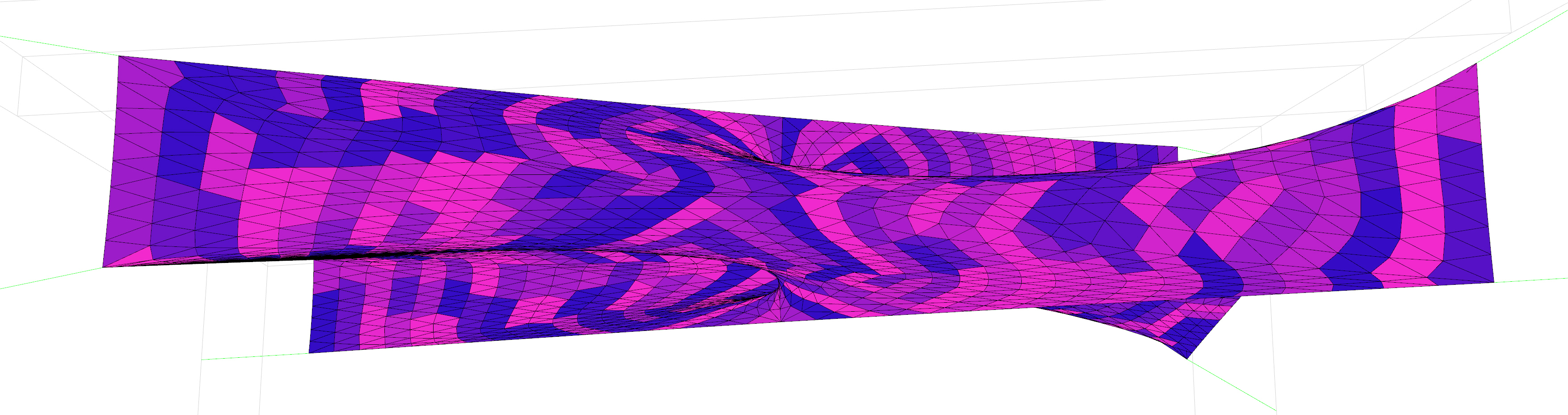

Geometry Segmentation Further mesh geometry processing involved unrolling based on primary and secondary segmentation with the grasshopper plug-in Ivy. After a short introduction, participants iterated through various segmentation strategies by trial and error in order to develop an understanding how each mesh walking algorithm unfolds on their geometry. Finally a strategy was chosen based on machine dimensions and material system properties. In a last step the segmentation strip layout was designed, which comprehended labelling, connector flaps and cutout meshgraph center lines.

Assembly Fabrication was rolled out at the second weekend as a roller coaster of technical hurdles and challenges due to the workshop’s ambitious goal and was only mastered by an extremely devoted team of participants and our supportive host. It turned out, that we had to increase the subdivision resolution of our mesh geometry once more in order to meet fabrication requirements due to machine size and material availability. Fab Lab generously sponsored some extra material to realize the intervention in full size and made us spot unicorns with their never ending supply of sweet cookies after 16h of laser cutting at 4 am. It was no surprise that some workshop participants developed ingenious broom supporting techniques during the collective installation of the final assembly.

Reflections An important key insight an installation of this size, material, and weight (!) taught us, is that the occurring forces in an tension-active structure should not be underestimated and investigations in appropriate connection design have to be emphasized. The chosen material system turned out to have reached a limit in this scale and ideas are underway for the next generation of complex mesh installations. Special thanks to: Daniel Hetzel, Natalie Peter and the Fab Lab for their courageous support and hospitality.

Comments 2