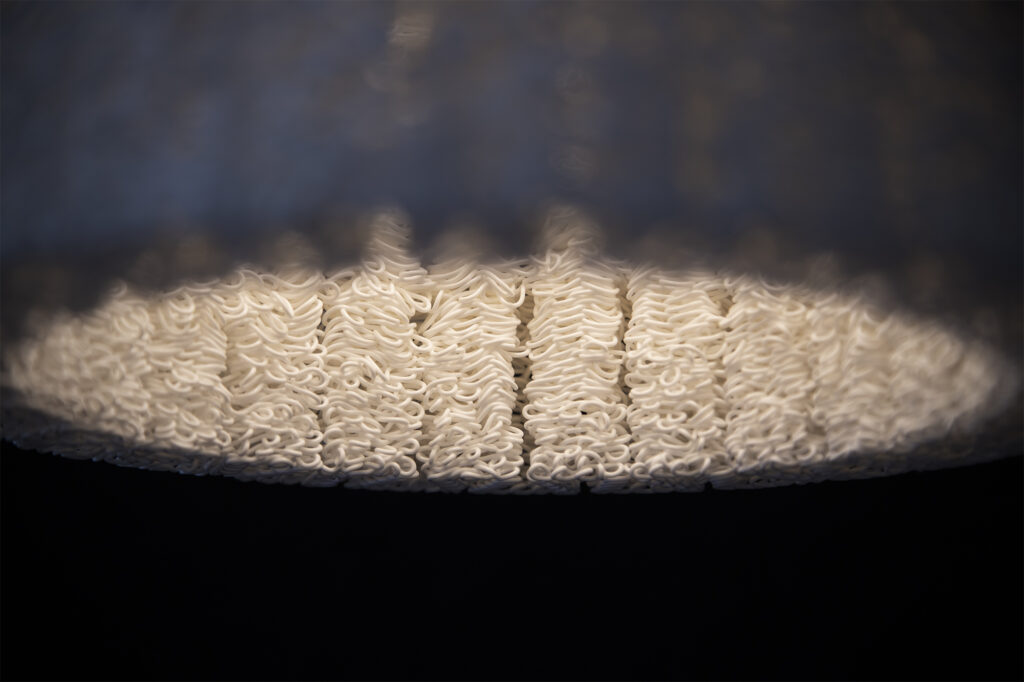

Type Research, Product

Size 400 x 600 mm

Weight 2000 g

Material PLA, PETG

Order on request

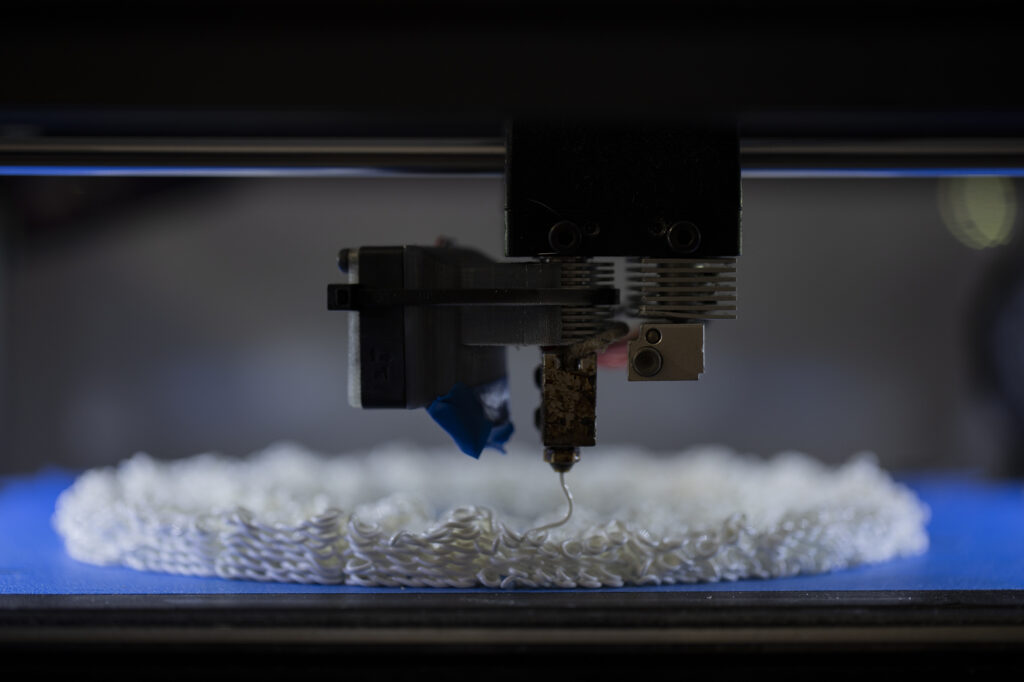

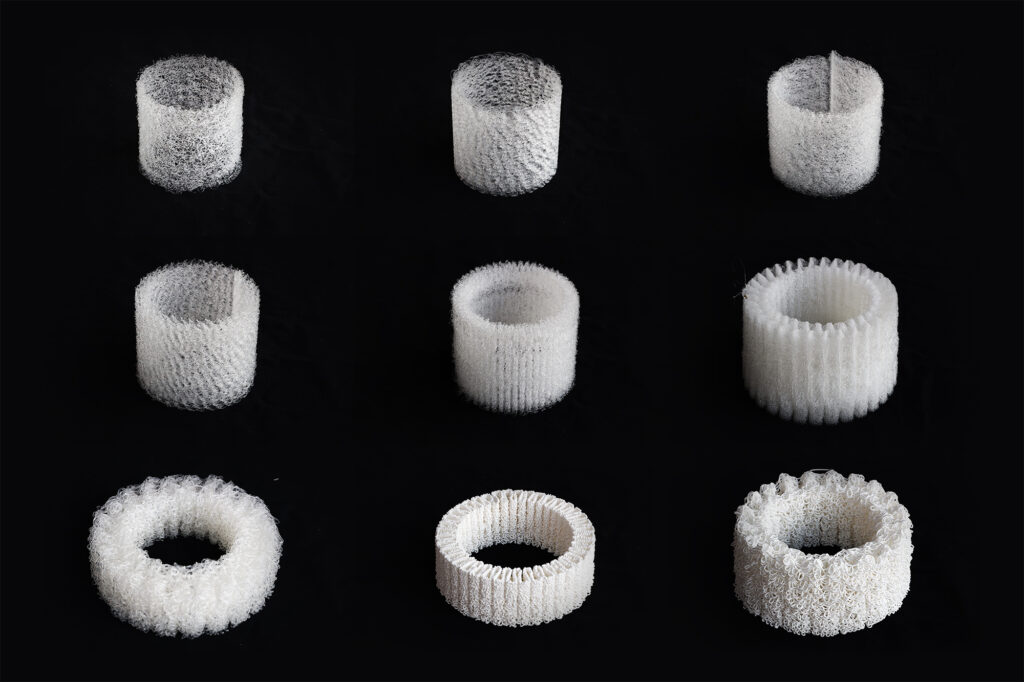

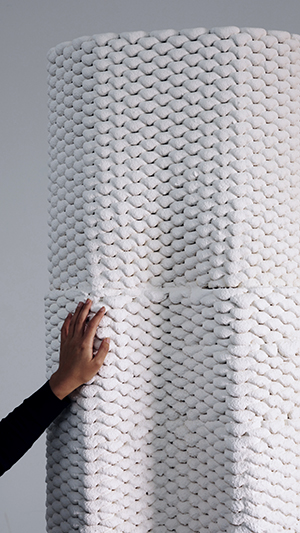

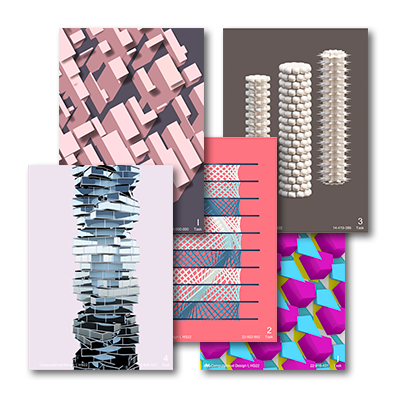

This study wasn’t inspired by ramen noodles. Instead, it explores the interplay of precise machine control and spontaneous material behaviour. Typically, 3D printers are used to fabricate perfect physical copies of digital geometry representations. In contrast to designing the form and materialising the identical replica, the design of the toolpath itself can lead to new material expressions and surprising articulations – through control and the lack thereof. The resulting porous structures can be differentiated in their density, translucency, stiffness, and overall delicacy.

Some tech details: the toolpaths were generated with Rhino/Grasshopper and exported with a custom G-code script. All prototypes and final pieces were printed with Raise3D Pro 2 printers in white and transparent PLA or PETG and nozzle diameters ranging between 0.4 to 1.2 mm. Early experiments focused on the effect of gradual z-offset changes. Later the single shell walls thickened into spatial patterns with overlaps and intersections of adjacent paths.