Robotic 3D Printing of Mineral Foam for a Lightweight Composite Concrete Slab

Authors Patrick Bedarf, Anna Szabo, Michele Zanini, Alex Heusi, Benjamin Dillenburger

Published in Proceedings of the 27th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Volume 2, 61-70

Year 2022

Recognition Best Paper Award

DOI 10.52842/conf.caadria.2022.2.061

Abstract

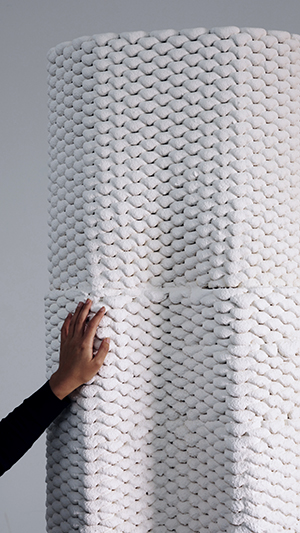

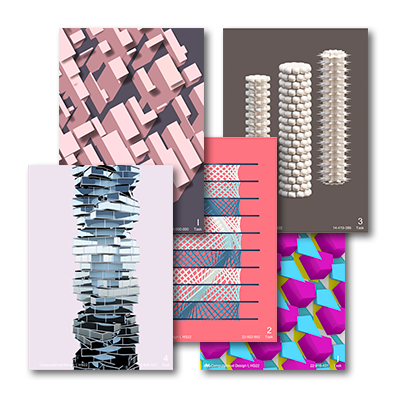

This paper presents the design and fabrication of a lightweight composite concrete slab prototype using 3D printing (3DP) of mineral foams. Conventionally, concrete slabs are standardized monolithic elements that are responsible for a large share of used materials and dead weight in concrete framed buildings. Optimized slab designs require less material at the expense of increasing the formwork complexity, required labour, and costs. To address these challenges, foam 3D printing (F3DP) can be used in construction as demonstrated in previous studies for lightweight facade elements. The work in this paper expands this research and uses F3DP to fabricate the freeform stay-in-place formwork components for a material-efficient lightweight ribbed concrete slab with a footprint of 2 x 1.3 m. For this advancement in scale, the robotic fabrication and material processing setup is refined and computational design strategies for the generation of advanced toolpaths developed. The presented composite of hardened mineral foam and fibre-reinforced ultra-high-performance concrete shows how custom geometries can be efficiently fabricated for geometrically complex formwork. The prototype demonstrates that optimized slabs could save up to 72% of total concrete volume and 70% weight. The discussion of results and challenges in this study provides a valuable outlook on the viability of this novel fabrication technique to foster a sustainable and resourceful future construction culture.